Home

>

Main Forum

>

Topic Re: Broke the block today. So, what did I find? |  |  |

| Broke the block today. So, what did I find? grant - 7 years ago |

Broke down the bottom end today: basically it breaks into two block halves and two crank carrier halves, plus a crank, and IMS, some chains and miscellany, and other small parts. Except for trapped oil int he IMS, all very clean. But some very worn - VERY worn.

A "top 7" list (they are all the rage, eh?) of what i found:

1. Scored cylinders on one side. *something* got in there, maybe before my ownership

2. some really smelly oil in the bearings and inside the IMS. Burnt. Ugly.

3. Burned and worn rod bearings - not good at all!

4. An LN IMS bearing that was in terrible shape, after only 3 years - albeit of track use. Pretty scary.

5. good rings

6. good chain guides and chains

7. The rods are "cracked" - i should have known that, but didn't. Still terrible, with the wear to prove it.

Why top 7? Not 10? I didn't think of ten things that were similarly interesting. I'm sure i forgot three, sorry.

Blocks is now off to Chicago, and I need to think about some decisions re: deep sump, IMS bearing (thinking DOF), X51 baffle in addition to Pedro's deep sump?, etc.

Grant

Grant

gee-lenahan-at-gee-mail-dot-com

A "top 7" list (they are all the rage, eh?) of what i found:

1. Scored cylinders on one side. *something* got in there, maybe before my ownership

2. some really smelly oil in the bearings and inside the IMS. Burnt. Ugly.

3. Burned and worn rod bearings - not good at all!

4. An LN IMS bearing that was in terrible shape, after only 3 years - albeit of track use. Pretty scary.

5. good rings

6. good chain guides and chains

7. The rods are "cracked" - i should have known that, but didn't. Still terrible, with the wear to prove it.

Why top 7? Not 10? I didn't think of ten things that were similarly interesting. I'm sure i forgot three, sorry.

Blocks is now off to Chicago, and I need to think about some decisions re: deep sump, IMS bearing (thinking DOF), X51 baffle in addition to Pedro's deep sump?, etc.

Grant

Grant

gee-lenahan-at-gee-mail-dot-com

| Re: Broke the block today. So, what did I find? MarcW - 7 years ago |

Quote

grant

Broke down the bottom end today: basically it breaks into two block halves and two crank carrier halves, plus a crank, and IMS, some chains and miscellany, and other small parts. Except for trapped oil int he IMS, all very clean. But some very worn - VERY worn.

A "top 7" list (they are all the rage, eh?) of what i found:

1. Scored cylinders on one side. *something* got in there, maybe before my ownership

2. some really smelly oil in the bearings and inside the IMS. Burnt. Ugly.

3. Burned and worn rod bearings - not good at all!

4. An LN IMS bearing that was in terrible shape, after only 3 years - albeit of track use. Pretty scary.

5. good rings

6. good chain guides and chains

7. The rods are "cracked" - i should have known that, but didn't. Still terrible, with the wear to prove it.

Why top 7? Not 10? I didn't think of ten things that were similarly interesting. I'm sure i forgot three, sorry.

Blocks is now off to Chicago, and I need to think about some decisions re: deep sump, IMS bearing (thinking DOF), X51 baffle in addition to Pedro's deep sump?, etc.

Grant

No pic of the scoring? Does a fingernail when dragged over the scored part catch ridges/grooves?

The inside of IMS can accumulate some oil over time and the inside of the IMS doesn't really get washed/flooded with oil and stagnant oil (mixed with combustion byproducts) can develop quite an odor.

Good rings is good but it doesn't seem to jive with scoring.

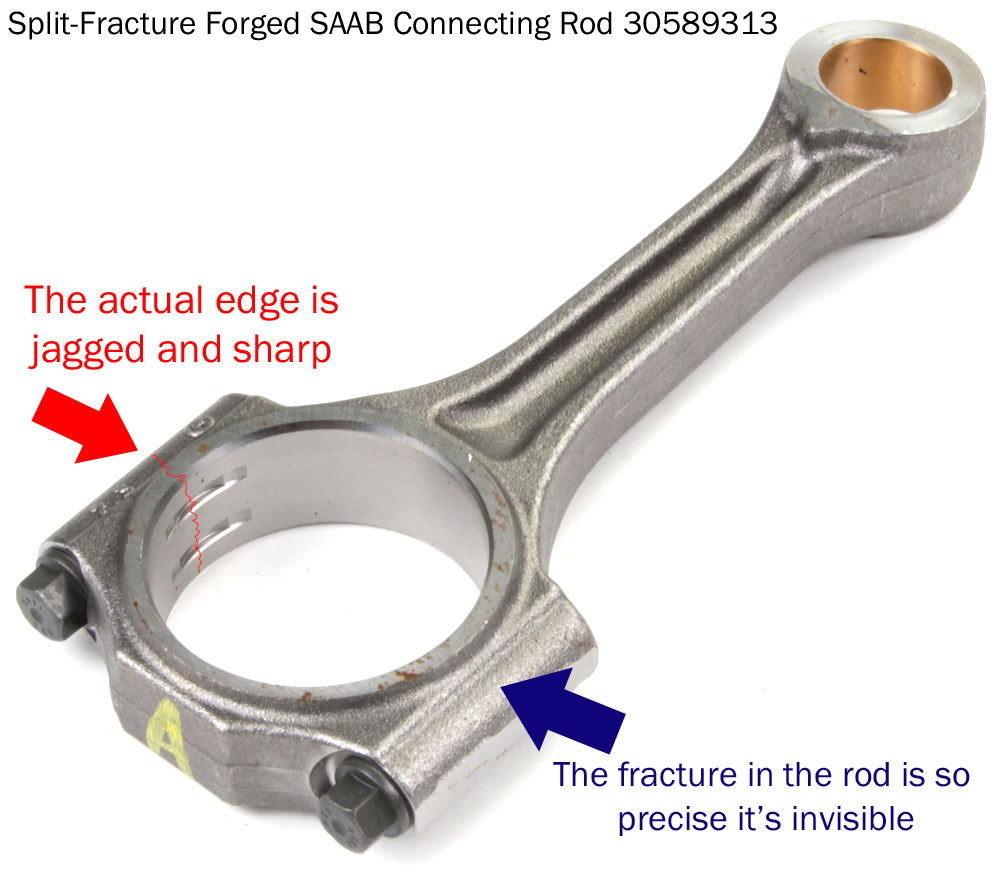

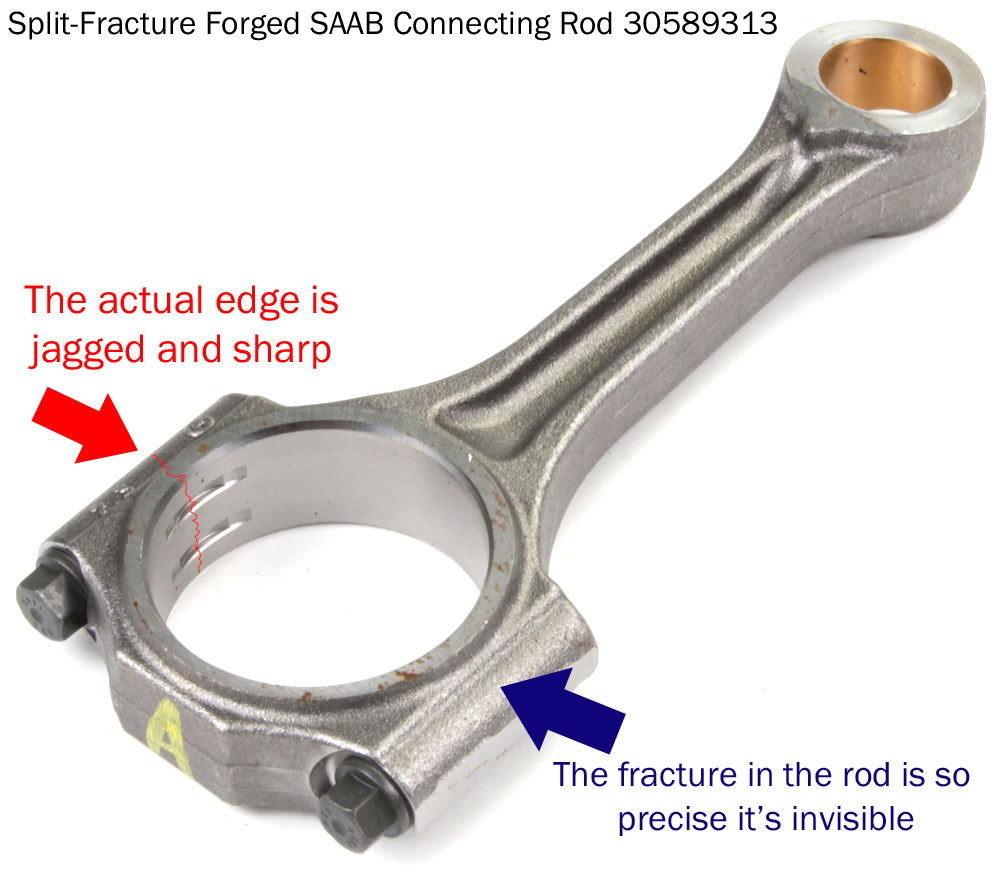

Cracked rods are very common. Eliminates a machining step (or two) and the halves fit back together perfectly. No risk in assembling the two halves slightly misaligned which can cause rod bearing grief.

Are you going for more displacement? Or just having the cylinders sleeved or ? and sized back to stock bore?

| Answers and comments grant - 7 years ago |

Hi Marc,

I'll give you a brief update - i posted the macro plan here some weeks back. I'm rebuilding the motor and tranny at and with the assistance of a top Porsche re builder locally. Very generous of him, and a great learning experience. I'm doing 3.2 --> 3.6 via Nickies (LN) which means a new, stronger liner which is also nikasil rather than locasil is inserted at the LN factory in Chicago, and then they return it, only with matched JE pistons which are metallurgically similar to minimize different expansion and consequent wear. Or that;'s the theory. Most race shops agree this is the best way forward for the bottom end,

I'm sending the tranny to GBOX in Colorado, the go-to re-builder. Synchros (1,2), diff whine, overall check and recon, likely LSD too (especialyl if i can deduct the cost of fixing the diff whine, which is likely).

The rest will be traditional local machining and rebuild- heads, polish crank, carillo rods, blah, blah. As noted, i still have a few detail decisions to make during the long gestation at LN. I believe i will put in the DOF for one - the IMS bearing felt awful. Startling to me. Clearly the LN is not up to this kind of abuse, and I'm more and more convinced by pedro's explanation that lubrication is the real culprit.

Hey, its only money. Gulp.

Now, to your questions:

No pic of the scoring? Does a fingernail when dragged over the scored part catch ridges/grooves?

--> i'll get some. A small number of fairly heavy vertical traces indicating a foreign object. I was pretty much out of time and had to clean up. I cant play too much hookey from work, my boss is a slave driver. (me)

The inside of IMS can accumulate some oil over time and the inside of the IMS doesn't really get washed/flooded with oil and stagnant oil (mixed with combustion byproducts) can develop quite an odor.

Yep, and now i've seen it. and smelt it!!! Like 150000 mile old transmission fluid. Rank.

Good rings is good but it doesn't seem to jive with scoring.

agree. go figure.

Cracked rods are very common. Eliminates a machining step (or two) and the halves fit back together perfectly. No risk in assembling the two halves slightly misaligned which can cause rod bearing grief.

Oh, yes, very familiar with the method. I was just surprised that they went to the trouble (and cost) since the rods and rod bearing are known to be under designed and stretch, then fail rapidly once out of round.

Are you going for more displacement? Or just having the cylinders sleeved or ? and sized back to stock bore?

As noted above - yes, but not by boring - by the LN 3.2-3.6 kit (you can read about it on their website). Seems pretty slick, durable. I'm hoping to pay more for robustness than power, but as you have seen, power would be useful for me :-) Even with all this I'll be in about the slowest car out there in terms of raw power: weight in black or red. I have been advised to be very careful if I was ever to bore out a 3.2 --> 3.somethingbigger because one loses both strength and silica density in the impregnated liner.

Right now I'm trying to ascertain the difference between wise upgrades along the way and good, old-fashioned "scope creep".

Your two cents always welcome. Four even, in this case.

Grant

gee-lenahan-at-gee-mail-dot-com

I'll give you a brief update - i posted the macro plan here some weeks back. I'm rebuilding the motor and tranny at and with the assistance of a top Porsche re builder locally. Very generous of him, and a great learning experience. I'm doing 3.2 --> 3.6 via Nickies (LN) which means a new, stronger liner which is also nikasil rather than locasil is inserted at the LN factory in Chicago, and then they return it, only with matched JE pistons which are metallurgically similar to minimize different expansion and consequent wear. Or that;'s the theory. Most race shops agree this is the best way forward for the bottom end,

I'm sending the tranny to GBOX in Colorado, the go-to re-builder. Synchros (1,2), diff whine, overall check and recon, likely LSD too (especialyl if i can deduct the cost of fixing the diff whine, which is likely).

The rest will be traditional local machining and rebuild- heads, polish crank, carillo rods, blah, blah. As noted, i still have a few detail decisions to make during the long gestation at LN. I believe i will put in the DOF for one - the IMS bearing felt awful. Startling to me. Clearly the LN is not up to this kind of abuse, and I'm more and more convinced by pedro's explanation that lubrication is the real culprit.

Hey, its only money. Gulp.

Now, to your questions:

No pic of the scoring? Does a fingernail when dragged over the scored part catch ridges/grooves?

--> i'll get some. A small number of fairly heavy vertical traces indicating a foreign object. I was pretty much out of time and had to clean up. I cant play too much hookey from work, my boss is a slave driver. (me)

The inside of IMS can accumulate some oil over time and the inside of the IMS doesn't really get washed/flooded with oil and stagnant oil (mixed with combustion byproducts) can develop quite an odor.

Yep, and now i've seen it. and smelt it!!! Like 150000 mile old transmission fluid. Rank.

Good rings is good but it doesn't seem to jive with scoring.

agree. go figure.

Cracked rods are very common. Eliminates a machining step (or two) and the halves fit back together perfectly. No risk in assembling the two halves slightly misaligned which can cause rod bearing grief.

Oh, yes, very familiar with the method. I was just surprised that they went to the trouble (and cost) since the rods and rod bearing are known to be under designed and stretch, then fail rapidly once out of round.

Are you going for more displacement? Or just having the cylinders sleeved or ? and sized back to stock bore?

As noted above - yes, but not by boring - by the LN 3.2-3.6 kit (you can read about it on their website). Seems pretty slick, durable. I'm hoping to pay more for robustness than power, but as you have seen, power would be useful for me :-) Even with all this I'll be in about the slowest car out there in terms of raw power: weight in black or red. I have been advised to be very careful if I was ever to bore out a 3.2 --> 3.somethingbigger because one loses both strength and silica density in the impregnated liner.

Right now I'm trying to ascertain the difference between wise upgrades along the way and good, old-fashioned "scope creep".

Your two cents always welcome. Four even, in this case.

Grant

gee-lenahan-at-gee-mail-dot-com

| Re: Answers and comments MarcW - 7 years ago |

Quote

grant

Hi Marc,

I'll give you a brief update - i posted the macro plan here some weeks back. I'm rebuilding the motor and tranny at and with the assistance of a top Porsche re builder locally. Very generous of him, and a great learning experience. I'm doing 3.2 --> 3.6 via Nickies (LN) which means a new, stronger liner which is also nikasil rather than locasil is inserted at the LN factory in Chicago, and then they return it, only with matched JE pistons which are metallurgically similar to minimize different expansion and consequent wear. Or that;'s the theory. Most race shops agree this is the best way forward for the bottom end,

I'm sending the tranny to GBOX in Colorado, the go-to re-builder. Synchros (1,2), diff whine, overall check and recon, likely LSD too (especialyl if i can deduct the cost of fixing the diff whine, which is likely).

The rest will be traditional local machining and rebuild- heads, polish crank, carillo rods, blah, blah. As noted, i still have a few detail decisions to make during the long gestation at LN. I believe i will put in the DOF for one - the IMS bearing felt awful. Startling to me. Clearly the LN is not up to this kind of abuse, and I'm more and more convinced by pedro's explanation that lubrication is the real culprit.

Hey, its only money. Gulp.

Now, to your questions:

No pic of the scoring? Does a fingernail when dragged over the scored part catch ridges/grooves?

--> i'll get some. A small number of fairly heavy vertical traces indicating a foreign object. I was pretty much out of time and had to clean up. I cant play too much hookey from work, my boss is a slave driver. (me)

The inside of IMS can accumulate some oil over time and the inside of the IMS doesn't really get washed/flooded with oil and stagnant oil (mixed with combustion byproducts) can develop quite an odor.

Yep, and now i've seen it. and smelt it!!! Like 150000 mile old transmission fluid. Rank.

Good rings is good but it doesn't seem to jive with scoring.

agree. go figure.

Cracked rods are very common. Eliminates a machining step (or two) and the halves fit back together perfectly. No risk in assembling the two halves slightly misaligned which can cause rod bearing grief.

Oh, yes, very familiar with the method. I was just surprised that they went to the trouble (and cost) since the rods and rod bearing are known to be under designed and stretch, then fail rapidly once out of round.

Are you going for more displacement? Or just having the cylinders sleeved or ? and sized back to stock bore?

As noted above - yes, but not by boring - by the LN 3.2-3.6 kit (you can read about it on their website). Seems pretty slick, durable. I'm hoping to pay more for robustness than power, but as you have seen, power would be useful for me :-) Even with all this I'll be in about the slowest car out there in terms of raw power: weight in black or red. I have been advised to be very careful if I was ever to bore out a 3.2 --> 3.somethingbigger because one loses both strength and silica density in the impregnated liner.

Right now I'm trying to ascertain the difference between wise upgrades along the way and good, old-fashioned "scope creep".

Your two cents always welcome. Four even, in this case.

The stock rods are forged and while even a forged rod can fail this doesn't appear to be a common failure. In fact I think with the stock rods the weakest link is with the rod bolts not the rods.

The "knock" against cracked rods is the big end can't be reworked. With a rod that has its big end halves machined these surfaces can be remachined to remove a bit of metal and then the halves bolted together and the rod's big end diameter machined/honed to bring it back to stock bearing size. 'course this requires a rod with enough extra metal at the big end to not be substantially weakened by this. This then requires the rod be overbuilt some and thus heavier and thus more prone to breaking or contributing to a crank failure.

Frankly I'd rather have a lighter rod. It is rare that a rod bearing can fail to the point the big end wears and has to be salvaged by the above procedure. Even if I encountered a rod that had experienced this wear I'd not bother to salvage it, even if it was a non-cracked rod, I'd just replace the rod and probably along with all the rest fo the rods. Whether I went with factory rods or aftermarket would depend.

There is no replacement for displacement, but with these engines bigger equals weaker. With a bigger bore the cylinder walls become thinner. A "stroker" keeps the cylinder bores either the same size or requires they not be machined as much to pick up the desired increase in displacement but a "stroker" brings with it its own problems. Higher piston speed and thus possibly a lower red line. Even so the crank/block experience more stress. The cylinders experience more pressure from the longer rods, too.

One is kind of damned if he does, damned if he doesn't... Stick with the stock engine size and its output. The engine probably lasts longer but the risk is the on track performance has one hoping the engine blows so he has an excuse to do a bigger/more powerful engine. Bump the engine's size and the power's there but the engine goes boom even with good aftermarket hardware installed.

| All true, all trade-offs, but from what i hear.... grant - 7 years ago |

The Nikkies are significantly stronger than what comes out so it should be more durable in that regard.

If I recall properly, Charles is actually a materials scientist, either rather than or in addition to an ME.

Of course more power means more stress and more heat, so its still more potential wear.

As to rods, as noted I'm putting in all new Carillo rods.

Not sure if its the bolts or the rods, (i've also heard about the bolts) but race shops ALL say the rods wear is a big deal on track cars that are run hard.

At this point they are junk, so its fairly academic. I do hop this lasts, its an expensive process.

Thanks again,

G

Grant

gee-lenahan-at-gee-mail-dot-com

If I recall properly, Charles is actually a materials scientist, either rather than or in addition to an ME.

Of course more power means more stress and more heat, so its still more potential wear.

As to rods, as noted I'm putting in all new Carillo rods.

Not sure if its the bolts or the rods, (i've also heard about the bolts) but race shops ALL say the rods wear is a big deal on track cars that are run hard.

At this point they are junk, so its fairly academic. I do hop this lasts, its an expensive process.

Thanks again,

G

Grant

gee-lenahan-at-gee-mail-dot-com

| On displacement vs. Strength, from LNE grant - 7 years ago |

Quote

MarcW

There is no replacement for displacement, but with these engines bigger equals weaker. With a bigger bore the cylinder walls become thinner. A "stroker" keeps the cylinder bores either the same size or requires they not be machined as much to pick up the desired increase in displacement but a "stroker" brings with it its own problems. Higher piston speed and thus possibly a lower red line. Even so the crank/block experience more stress. The cylinders experience more pressure from the longer rods, too.

One is kind of damned if he does, damned if he doesn't... Stick with the stock engine size and its output. The engine probably lasts longer but the risk is the on track performance has one hoping the engine blows so he has an excuse to do a bigger/more powerful engine. Bump the engine's size and the power's there but the engine goes boom even with good aftermarket hardware installed.

I realize this is the manufacturer's marketing claims, but many shops support it. From the LNE site:

"Nickies utilize a highly wear resistance cylinder bore plating (NSC - which stands for nickel, silicon, and carbide) for long life, which is very similar to Nikasil™, as used on the Carrera GT, GT2, GT3, and 911 Turbo engines! Nickies™ feature our superior aluminum alloy up to 66% stronger than than the cast in Lokasil™ bores or MMC sleeves, providing for improved thermal conductivity and reduced wear and friction over original or cast iron sleeves, and allow for larger bores without any loss of strength or longevity." - LN Engineering Web Site; nickies; 3.2-->3.6 kit

This is one of several reasons I chose the nickies approach rather than boring. The others being 2) nikasil vs locasil, 3) matched to JE pistons, 4) better machining QC vs a manual machine shop

Again, i can't see the future, but i can be hopeful..

Grant

Grant

gee-lenahan-at-gee-mail-dot-com

Edited 2 time(s). Last edit at 01/15/2017 12:41PM by grant. (view changes)

| Re: Answers and comments SteveJ (2010 987 base, manual trans) - 7 years ago |

frogster - 7 years ago |

grant, what exactly do you mean by cracked rods? i would take it at literal value, meaning that there are cracks in the rods, but after reading marc's comments, i'm left wondering if that's right. why would you put broken rods back together?

--

MY 2000 S, Ocean Blue, Metropol Blue, Savanah Beige.

Bought June 2000 - Sold May 2010

--

MY 2000 S, Ocean Blue, Metropol Blue, Savanah Beige.

Bought June 2000 - Sold May 2010

| "Cracked or Fractured Rods" grant - 7 years ago |

The weakest link in a connecting rod is often the circular part that connects to the crankshaft. It must be two pieces, and be a precise fit.

Recently (20 years?) the best process is to cast a single piece rod, and precisely fracture it so that it fits *perfectly* and self-aligns. That is a cracked rod. See below:

The rods in M96 motors, to my surprise, are cracked type. I say surprise because i have heard legion about this being a weak point - weak bolts, weak rod, stretching, failure. I plan to put in carillo rods to alleviate the problem.

Grant

Grant

gee-lenahan-at-gee-mail-dot-com

Recently (20 years?) the best process is to cast a single piece rod, and precisely fracture it so that it fits *perfectly* and self-aligns. That is a cracked rod. See below:

The rods in M96 motors, to my surprise, are cracked type. I say surprise because i have heard legion about this being a weak point - weak bolts, weak rod, stretching, failure. I plan to put in carillo rods to alleviate the problem.

Grant

Grant

gee-lenahan-at-gee-mail-dot-com

frogster - 7 years ago |

MikenOH - 7 years ago |

Quote

grant

Broke down the bottom end today: basically it breaks into two block halves and two crank carrier halves, plus a crank, and IMS, some chains and miscellany, and other small parts. Except for trapped oil int he IMS, all very clean. But some very worn - VERY worn.

A "top 7" list (they are all the rage, eh?) of what i found:

1. Scored cylinders on one side. *something* got in there, maybe before my ownership

2. some really smelly oil in the bearings and inside the IMS. Burnt. Ugly.

3. Burned and worn rod bearings - not good at all!

4. An LN IMS bearing that was in terrible shape, after only 3 years - albeit of track use. Pretty scary.

5. good rings

6. good chain guides and chains

7. The rods are "cracked" - i should have known that, but didn't. Still terrible, with the wear to prove it.

Why top 7? Not 10? I didn't think of ten things that were similarly interesting. I'm sure i forgot three, sorry.

Grant

A couple questions:

1) Miles on the motor prior to you buying it; miles on it after you installed it with the new IMS?

2) IIRC, this motor was burning oil at the end; had that always been the case from day one of your ownership?

3)LN IMS--ceramic? Was it coming apart or pitted? Agreed- if a replacement IMS was that worn after 3 years (40K miles?) then it probably wasn't up tot he job. A friend that just lost a motor in a 997.1 due to a IMS sprocket slipping, reported his stock IMS was perfect when pulled from the motor during the tear down--55K on the motor with 10K track miles.

4) Worn rod bearings--if there was material scoring the cylinder walls, would that contribute to the buggered up rod bearing or is this a mileage/rev issue? Where all all worn or just a few?

5) Oil stuck in the IMS--were the oil seals still in place? No way to get the oil out of it going forward?

| Re: Broke the block today. So, what did I find? grant - 7 years ago |

Quote

MikenOH

Grant

A couple questions:

1) Miles on the motor prior to you buying it; miles on it after you installed it with the new IMS?

2) IIRC, this motor was burning oil at the end; had that always been the case from day one of your ownership?

3)LN IMS--ceramic? Was it coming apart or pitted? Agreed- if a replacement IMS was that worn after 3 years (40K miles?) then it probably wasn't up tot he job. A friend that just lost a motor in a 997.1 due to a IMS sprocket slipping, reported his stock IMS was perfect when pulled from the motor during the tear down--55K on the motor with 10K track miles.

4) Worn rod bearings--if there was material scoring the cylinder walls, would that contribute to the buggered up rod bearing or is this a mileage/rev issue? Where all all worn or just a few?

5) Oil stuck in the IMS--were the oil seals still in place? No way to get the oil out of it going forward?[/quote]

1. Not sure how many miles, low-ish - maybe 50k in 12 years - likey oil rarely changed and run cold often. If you recall "we" (the board) had this discussion recently

1a. 39k since installation, including ~ 7500 track miles - the rest is normal drving or to/from tracks

2. it always burned some, but no, it got progressively worse. note: "burn" is a funny term - it was apparently being sucked in via the AoS due to crankcase pressure - as well as via rings/etc. Under normal driving it burned little or no oil, and also burned vastly less on track in left hand turns. You may recall extensive discussion and documentation on this that i wont repeat.

3. Yes - LN replacement IMS. Cant yet tell if it was pitted, as noted its not off the IM shaft yet due to puller issues. But the cage is VERY loose and it wobbles like a weeble.

4. Nah, the rod wear is typical - burning and elongation where they take the highest stress. Known failure mode of hard driven M96s. No scoring - just rapid wear

5. hat seals do you refer to? Its hard to get the oil out of the IMS - no where for it to go really ( note: we are talking the IMS - intermediate shaft, not the IMS end-bearing that gets all the attention, and is imprecisely abbreviated "IMS"; s=shaft). The shaft itself is hollow, and traps oil, which becomes acid. The bearing engineer noted that the old, acid, oil might be a contributor to the demise of IMS *bearings* which are slowly fed some of it.

The rod issue can be reduced with a) better rods and b) better lubrication. I'm almost certainly using carillo rods.

I have three tricks i want to try for lubrication:

1. now my sump is modified to work properly all the time - there were times it could have starved due to oil trapped above the windage tray - sump doing the opposite of what it was intended to do.

2. DOF - maybe (only helps the IMS, not rods)

3. DIY dry sump (if i can make it work - biggest issue is scavenging reliably)

IMS is another story. I'm really hoping the DOF is the answer. I want to do a bit of sleuthing. Wish there was better field data. Unfortunately much published data on all failures comes from folks with money to be made on other fixes.

Grant

Grant

gee-lenahan-at-gee-mail-dot-com

MikenOH - 7 years ago |

Quote

grant

The rod issue can be reduced with a) better rods and b) better lubrication. I'm almost certainly using carillo rods.

I have three tricks i want to try for lubrication:

1. now my sump is modified to work properly all the time - there were times it could have starved due to oil trapped above the windage tray - sump doing the opposite of what it was intended to do.

2. DOF - maybe (only helps the IMS, not rods)

3. DIY dry sump (if i can make it work - biggest issue is scavenging reliably)

IMS is another story. I'm really hoping the DOF is the answer. I want to do a bit of sleuthing. Wish there was better field data. Unfortunately much published data on all failures comes from folks with money to be made on other fixes.

Grant

Grant

Thanks for the reply.. It sounds like you've got a good plan going forward for a robust, powerful track car.

Regarding the IMSB on the new motor--what will be used?

The DOF should help keep whatever bearing you decide on alive longer than the stock setup.

Regarding consistent oil pressure to keep the new rods lubed, the thoughts on the sump sounds interesting. Does an Accusump enter into this equation at all?.

IIRC, Jake was one of the guys beating the drum that excessive heat temps in the engine compartment was one of the prime culprits in engine failures. Are you doing anything along those lines to get the heat out?

BTW, I found a thread on oil temps/oil pressure at the track on a site with plotted data in a M96 motor which might be helpful.

Sorry, only registered users may post in this forum.