Home

>

Main Forum

>

Topic Never did managed to get the tension pin in... |  |  |

| Anyone with tips on how best to insert a tension pin? RainyDayGarage - Monday, 22 April, 2013, at 1:17:17 pm |

Took the hardtop off the Boxster this weekend and discovered why it was squeaking all Winter long.

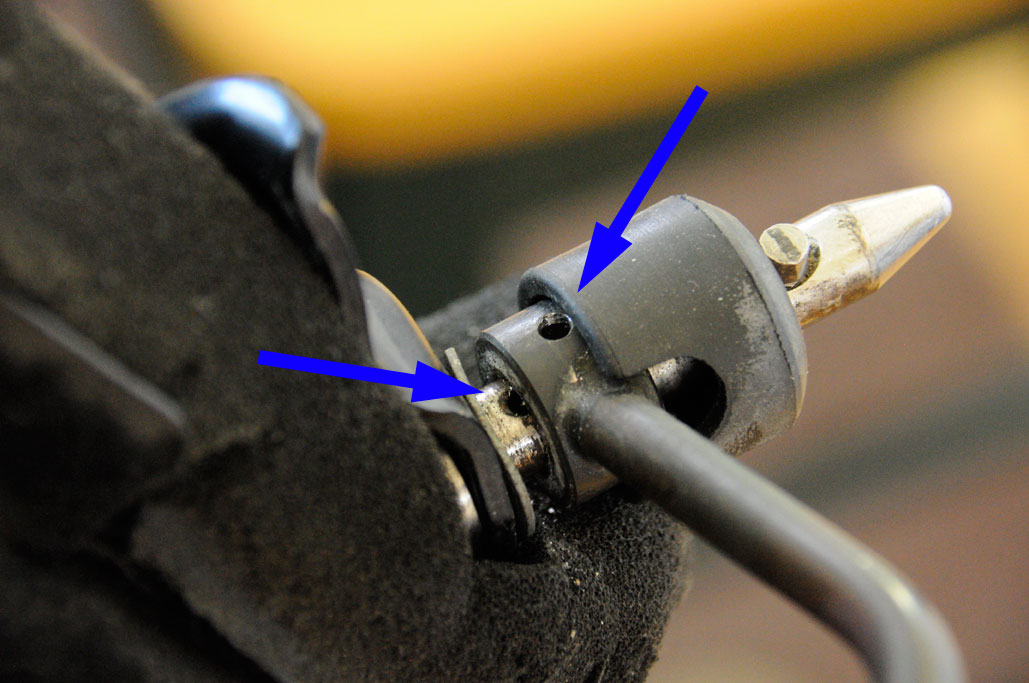

One of the levels which locks the top down to the car had a broken tension pin. The pin goes through the lever into the stem that locks the top down to the car, joining the two piece together. With the pin broken, the level can slides along the stem...hence the annoying squeak, not to mention a slightly loose top on one side.

Anyway, got the three broken pieces of the tension pin out (1/8" diameter, 3/4" long) of the level and the stem, but can't seem to get a new steel tension pin back in.

The problem is how to squeeze the pin to slide it in? Or do you have to hammer it in?

Thought I would ask to see if there is a trick to this before I just insert a thinner steel bolt and cap it off with a spring washer and a nut.

One of the levels which locks the top down to the car had a broken tension pin. The pin goes through the lever into the stem that locks the top down to the car, joining the two piece together. With the pin broken, the level can slides along the stem...hence the annoying squeak, not to mention a slightly loose top on one side.

Anyway, got the three broken pieces of the tension pin out (1/8" diameter, 3/4" long) of the level and the stem, but can't seem to get a new steel tension pin back in.

The problem is how to squeeze the pin to slide it in? Or do you have to hammer it in?

Thought I would ask to see if there is a trick to this before I just insert a thinner steel bolt and cap it off with a spring washer and a nut.

| Re: Some pics RainyDayGarage - Monday, 22 April, 2013, at 3:22:50 pm |

| Re: Some pics MauriceonLongIsland - Saturday, 27 April, 2013, at 11:58:17 am |

You may be able to use a small pair of vise-grips, squeezing the pin about 1/4 inch away from the end. That should give you enough length for the pin to enter the lever and start to enter the steel rod. Then you can tap it in with a small hammer (or a drift).

If that does not give you quite enough clearance, you can use the same method, but first grind down the leading edge of the pin at a steeper angle than the factory bevel. That will make it a little more "pointy" and easier to insert past the inner hole.

Regards, Maurice.

If that does not give you quite enough clearance, you can use the same method, but first grind down the leading edge of the pin at a steeper angle than the factory bevel. That will make it a little more "pointy" and easier to insert past the inner hole.

Regards, Maurice.

| Never did managed to get the tension pin in... RainyDayGarage - Sunday, 12 May, 2013, at 7:53:09 pm |

The problem was trying to press the pin in while gripping a curved surface with the clamp.

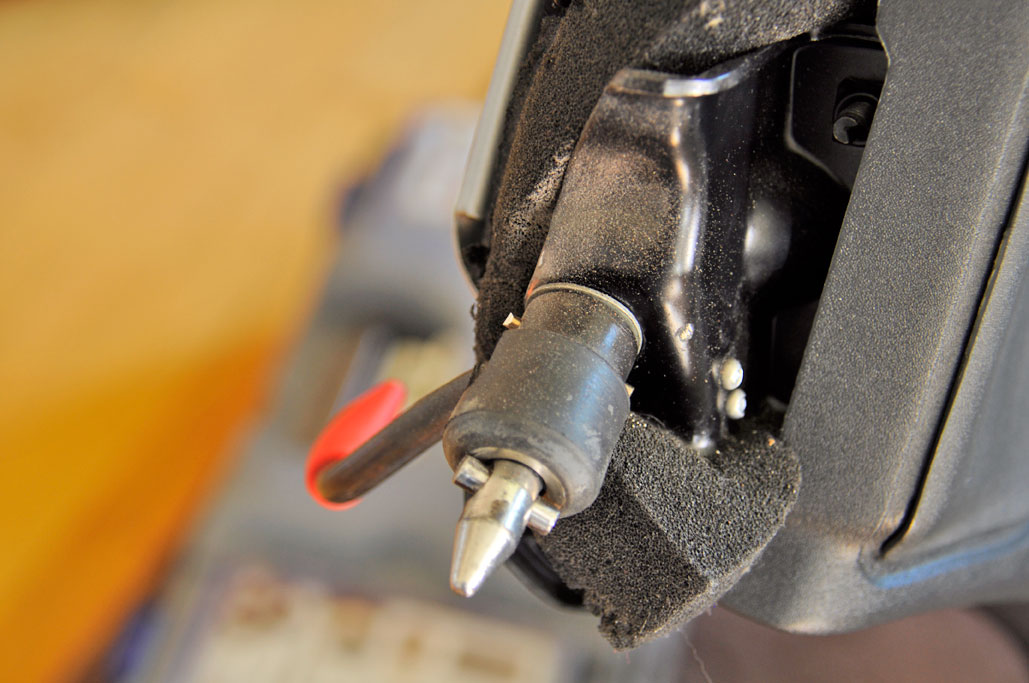

Decided to go with a hack to fix the problem...

1. matched the hole with the same size drill bit:

2. cutter blade on Dremel:

3. drill bit cut:

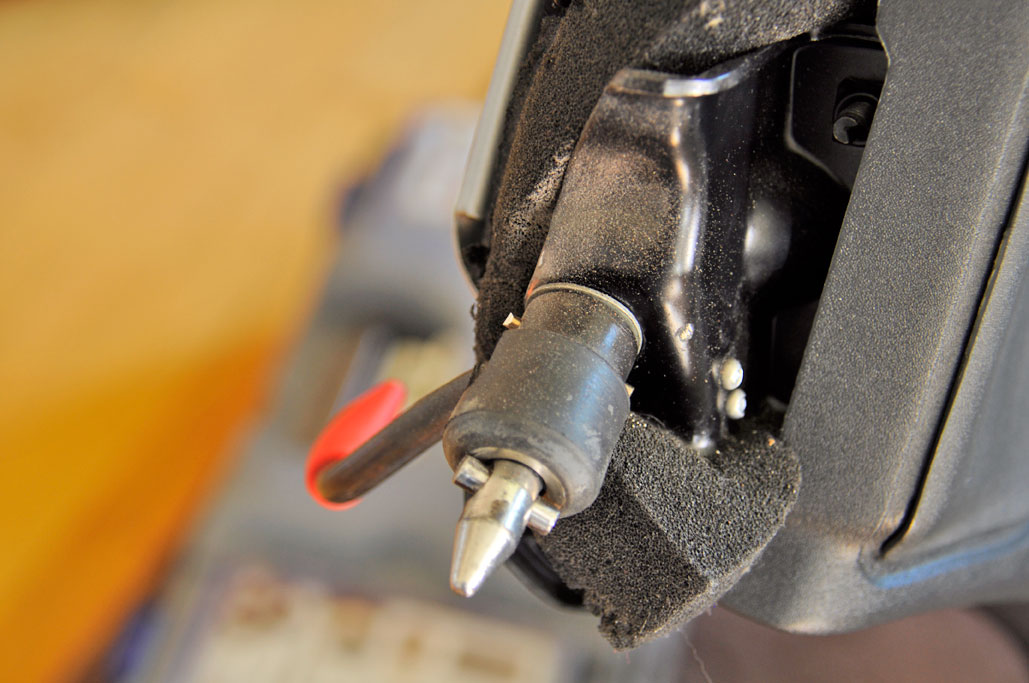

4. repaired:

The pin is held in by both the sleeve and a spring washer (visible in one of the previous pics).

Pretty sure this fix should hold up under use.

Decided to go with a hack to fix the problem...

1. matched the hole with the same size drill bit:

2. cutter blade on Dremel:

3. drill bit cut:

4. repaired:

The pin is held in by both the sleeve and a spring washer (visible in one of the previous pics).

Pretty sure this fix should hold up under use.

Sorry, only registered users may post in this forum.